Robots have leapt out of science-fiction and into the mainstream factory floor, quietly becoming the muscle, speed, and precision behind the products we rely on every day. From aerospace components to artisanal coffee machines, advanced robotic automation is reshaping the competitive landscape. Yet many operations managers still wonder: Is robotic automation truly worth the investment, and-if so-how do I choose among the many robotic automation companies, custom automation solutions, and industrial automation suppliers in the market?

At McIver Engineering & Controls, we live and breathe these questions. As an exclusive robotic partner of FANUC-the global leader with over 1 million robots installed worldwide-and a proud FANUC Authorized System Integrator (ASI), we design turnkey solutions that blend world-class hardware with tailored SME Services. Let’s unpack why manufacturers embrace robots and how our partnership with FANUC translates into real-world value.

1. Precision & Consistency That Humans Can’t Match

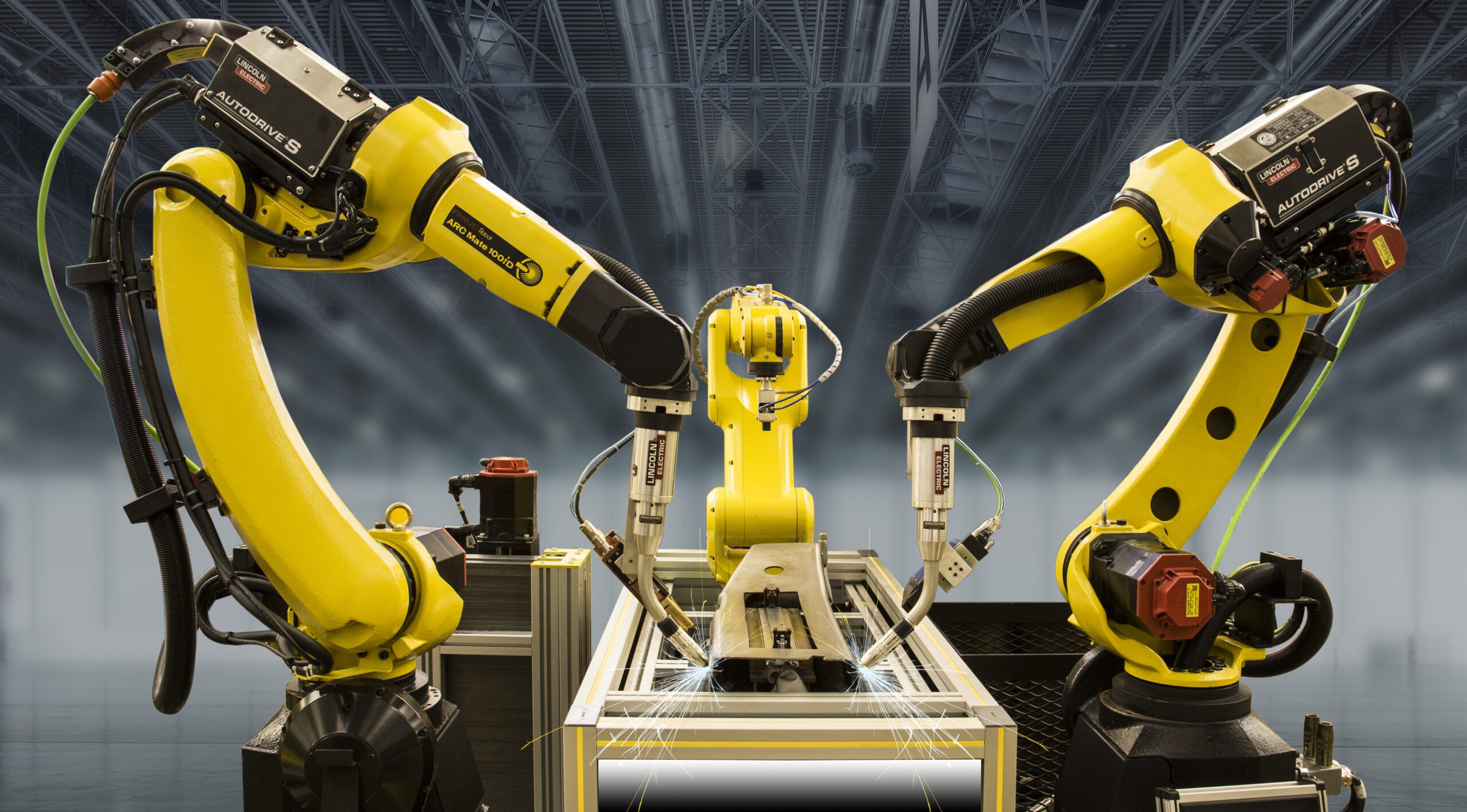

Quality is no longer a differentiator; it’s the ticket to staying in business. Whether you’re laser-welding titanium turbine blades or packaging cold-chain pharmaceuticals, every variation risks warranty claims, recalls, or lost customer trust. Robots shine by repeating sub-millimeter motions 24 hours a day. FANUC arms, for example, promise ±0.02 mm repeatability across millions of cycles-a performance envelope humans simply can’t maintain.

By integrating these robots with vision systems and closed-loop feedback, McIver Engineering delivers custom automation solutions that keep CpK values high, drive first-pass yield above 98 percent, and slash scrap costs.

2. Higher Throughput, Shorter Lead Times

Speed and uptime dictate profitability. A single FANUC M-20iD/35 robot can perform a pick-and-place in under 0.9 seconds, replacing two operators per shift and running without breaks. Imagine you’re a Tier-1 automotive supplier and production demand skyrockets. Wouldn’t it be amazing if your custom industrial automation cell could double output, from 50 to 100 units per hour, improving revenue per square foot? Our team and FANUC’s offerings turn the seemingly impossible into reality.

Reducing cycle time in manufacturing creates positive downstream effects: inventory levels decrease, order-to-ship times shorten, and customers see the difference. When your production line boosts output without relying on overtime, you gain stronger negotiating power and greater agility in the market.

3. Flexibility for High-Mix, Low-Volume Orders

Once upon a time, robots made sense only for million-unit runs. Not anymore. FANUC’s R-30iB Plus controller hosts user-friendly iPendant Touch interfaces and offline ROBOGUIDE simulation, while McIver Engineering & Controls designs traditional end-of-arm tooling (EOAT) such as quick-change grippers using 3D-printed tool nests or adaptive vacuum arrays.

The upshot? You can pivot from Product A to Product B in seconds to minutes-ideal for contract manufacturers, electronics assemblers, or medical-device firms juggling dozens of SKUs. Our industrial automation suppliers network ensures every peripheral (conveyors, barcode readers, torque tools) plugs seamlessly into small external PLC offerings or directly to the robot PLC, supporting future expansions.

4. Safety & Ergonomics

Manually palletizing 50-lb cases or deburring cast iron creates strain injuries and turnover. Robots remove operators from dirty, dangerous, or bottleneck jobs, reallocating them to quality inspection, line supervision, or robot programming-roles that upskill the workforce and lower workers’ comp premiums.

With FANUC’s Dual-Check Safety (DCS) and McIver-designed guarding, our cells often win insurance rebates and OSHA accolades. Collaborative robots (cobots) like the FANUC CRX series further enhance safety, sharing space with humans without hard fencing.

5. Data-Driven Continuous Improvement

Digital transformation isn’t a buzzword; it’s the next profit lever! Robots equipped with Force Sensors, iRVision, and EthernetIP deliver real-time data on cycle times, force signatures, and predictive maintenance metrics. McIver Engineering & Controls has the ability to integrate these signals from a PLC into your MES or cloud dashboards, enabling OEE dashboards and AI-driven anomaly detection.

Why Partner with McIver Engineering & Controls and FANUC?

| Evaluation Area | Standard Supplier | McIver Engineering + FANUC |

|---|---|---|

| Robot Hardware | Mix of brands with varied support | Exclusive FANUC portfolio: 0.5 kg to 2.3 ton payloads, ISO-certified reliability |

| System Integration | Outsourced programming and debug | In-house mechanical, controls, and software teams; rapid FAT/SAT cycles |

| Service & Spare Parts | 3-5 day lead times | FANUC’s 24/7 parts hotline + McIver’s regional field techs |

| Evaluation Area | Standard Supplier | McIver Engineering + FANUC |

|---|---|---|

| Lifecycle Upgrades | Rip-and-replace model | Modular design for future robot, gripper, or line-tracking add-ons |

| Training & Support | Generic manuals | On-site operator training, ICP (Integration Certification Program), plus e-learning |

Being an ASI partner means McIver Engineering & Controls has met FANUC’s rigorous standards in technical capability, application success, and customer satisfaction. You benefit from:

- Priority tech support – direct engineering hotlines, not call centers.

- Early access to new robot models – test the latest SCARA or CR cobots before wider release.

- Co-developed risk assessments – jointly authored safety documentation streamlines plant insurance audits.

Implementation Roadmap: From Imagination to In-Production

- Feasibility & ROI Modeling

We analyze your takt times, labor rates, and floor layout. A typical cell pays back in 14-24 months. - Simulation & Virtual Commissioning

Using FANUC ROBOGUIDE, we craft digital twins to validate reach, cycle time, and collision zones-long before steel is cut. - Fabrication & Factory Acceptance Testing (FAT)

Our Wisconsin facility builds, wires, and programs the cell. You witness a 100 percent-functional system before shipment. - On-Site Install & Start-Up

Most cells are production-ready within 3-5 days, thanks to pre-commissioning. Our technicians stay until solution performance meets contract benchmarks. - Training & Continuous Improvement

From operator “teach-pendant basics” to advanced I/O diagnostics, we transfer knowledge. Post-launch audits track KPIs and identify future automation candidates.

It All Comes Down to the Bottom Line

Manufacturers adopt robots for a simple reason: they sharpen competitiveness across quality, speed, safety, and data. When you combine FANUC’s industry-leading robots with McIver Engineering’s bespoke integration expertise, you gain more than a machine-you secure a scalable production asset backed by two organizations obsessed with uptime.

If you’re exploring robotic automation companies or need custom automation solutions that align with lean initiatives and ROI targets, then let’s start a conversation. As a trusted partner among industrial automation suppliers, McIver Engineering & Controls stands ready to design, build, and support the next leap in your manufacturing evolution.

Schedule a complimentary feasibility assessment today and discover how smart robotics can future-proof your operation.

McIver Engineering & Controls – bridging innovative ideas and world-class manufacturing, together with FANUC.