Food And Beverage Industry Solutions

Custom Automation Solutions for Food and Beverage Production

Reliable Industrial Control Panels for Food and Beverage Operations

Engineering Services for Industrial Controls & Automation

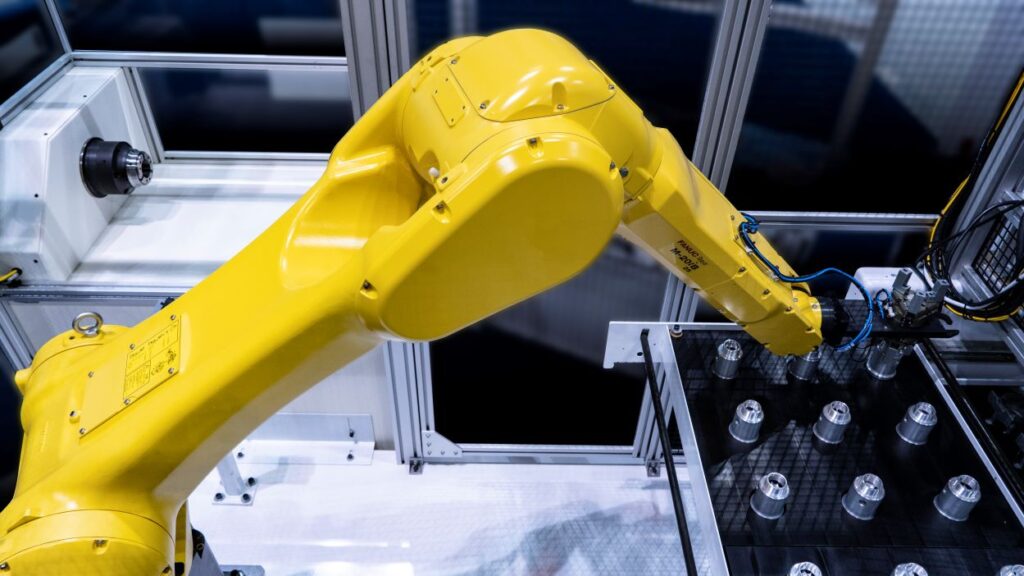

Our industrial control panels and robotic automation solutions are fully customizable to meet the precise needs of food and beverage production. Each system is engineered for safety, consistency, and efficiency—helping you maintain product integrity and streamline operations. Key capabilities include:

- Conveyor and batching control: Regulate speed, direction, and ingredient ratios for smooth, accurate processing.

- Robotic quality control: Automate inspection to ensure consistency and reduce waste.

- End-of-line packaging: Improve speed and precision in packing, sealing, and labeling.

- Warehouse automation and palletization: Optimize logistics with robotic palletizing and integrated warehouse control systems.

At McIver Engineering & Controls, our engineers collaborate closely with your team to design and integrate control panels and robotic systems that fit seamlessly into your existing processes. From concept through commissioning, we focus on boosting productivity, reducing downtime, and elevating product quality.

Transform Your Food and Beverage Operations

Partner with McIver to bring precision automation and robotics to every stage of production. Contact us today to get started.

Ready to Get Started?

Request a Quote for Your Food and Beverage Automation Project

Connect with

Our Team

Smarter, Safer, and More Efficient Production

In today’s fast-paced manufacturing world, efficiency and consistency are no longer optional. Manufacturers face constant pressure to deliver higher output, greater precision, and shorter cycle times. Robotic machine tending has

In today’s competitive manufacturing environment, automating material handling has become essential for improving efficiency, reducing manual labor, and maintaining product consistency. Choosing the best palletizing and depalletizing system requires more

In today’s competitive manufacturing landscape, accuracy, consistency, and efficiency define success. As global markets demand higher output and uncompromising quality, manufacturers are increasingly turning to industrial automation to stay ahead.