End-to-End Robotic Solutions That Deliver

Robotic Automation, Built Around Your Business

At McIver Engineering & Controls, we design robotic solutions tailored to your unique applications, boosting efficiency, safety, and performance across any industry.

Meet the Systems that Deliver

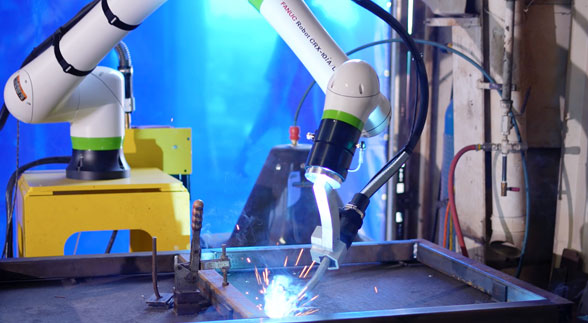

From the Cobot CRX 25iA to the M-410 to the R-1000iA, McIver can automate your end-of-line with almost any configuration. From automotive to pharmaceutical to food, end-of-line robotic McIver has all the experience you need: From case erection, then bag insertion with cuffing, to robotic case filling, case de-cuffing and closure, to taping, labeling, sorting, and finally robotic palletizing – McIver has done it all. Integrating Fanuc, or your brand of robot, is what we do.

Proven systems, Powerful results,

Explore our core solutions today.

Whether you need robotic palletizing, control panels, or full-scale automation, McIver Engineering & Controls provides turnkey systems that deliver measurable success.

Smarter Welding Automation Starts Here

Boost Production with Robotic Assembly Automation

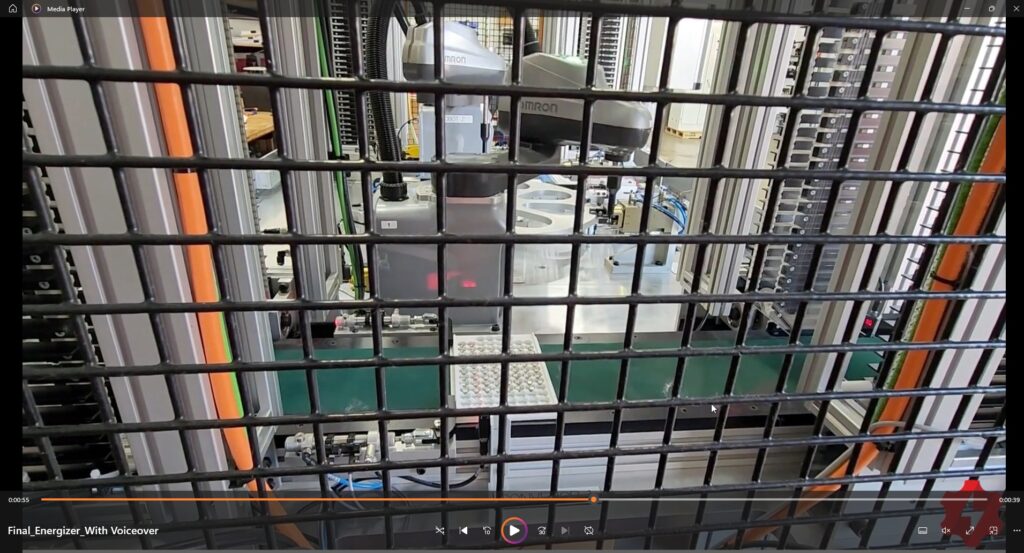

Smarter Mold and Machine Tending Automation

Manual tending tasks often slow production and expose workers to challenging conditions. McIver Engineering & Controls designs robotic machine tending systems that integrate seamlessly with your current equipment. Our automation boosts throughput by as much as 40%, enhances safety, and enables lights-out production when paired with pre-feeding and post-process solutions.

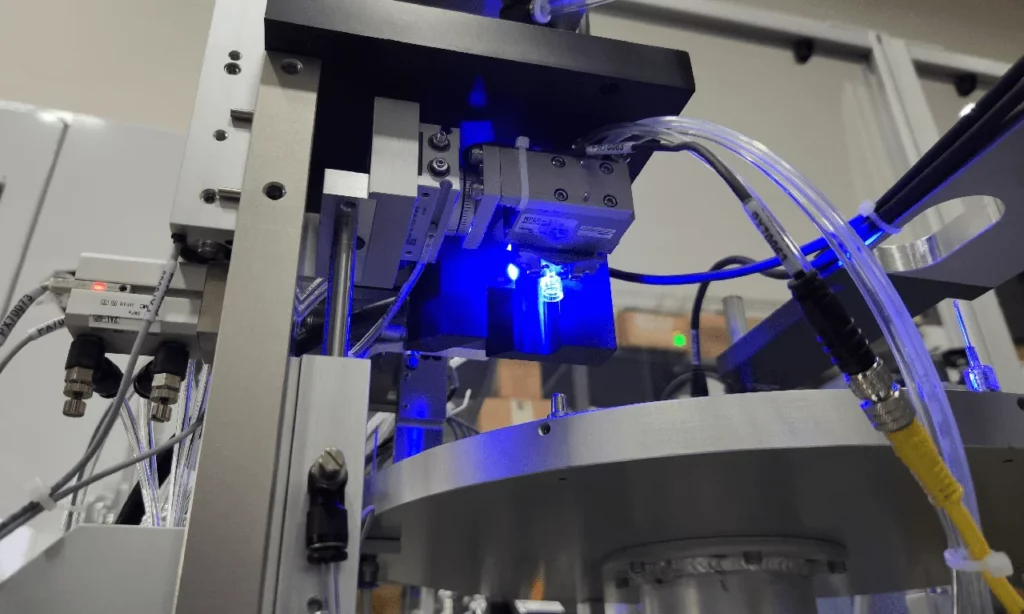

Custom Robotic Systems for Testing & Inspection

From batteries to motors and microchips, production testing can be complex when relying on manual operator lines. McIver Engineering & Controls designs and builds robotic automation cells with custom feed systems to simplify testing, enhance accuracy, and increase throughput. Our engineers design solutions tailored to your needs, helping you overcome obstacles and optimize production.

Proven Robotic Automation in Action

Get to Know Robotic Automation

In what types of applications are robots a better choice than fixed automation?

What industries benefit most from robotic automation?

What is industrial robotic automation?

What are the main benefits of implementing robotic automation?

How long does it take to see a return on investment (ROI)?

How flexible are industrial robots?

Robotic Automation Blog & Industry Insights

Explore articles on industrial automation, robotic palletizing, end-of-line packaging, and FANUC robotic systems. McIver Engineering & Controls shares expertise, case studies, and best practices to help manufacturers improve productivity, safety, and ROI.

In today’s competitive manufacturing environment, automating material handling has become essential for improving efficiency, reducing manual labor, and maintaining product consistency. Choosing the best palletizing and depalletizing system requires more

In today’s competitive manufacturing landscape, accuracy, consistency, and efficiency define success. As global markets demand higher output and uncompromising quality, manufacturers are increasingly turning to industrial automation to stay ahead.

In today’s manufacturing environment, efficiency and precision define success. Industrial automation has become the cornerstone of modern production, and leading robotic automation companies are helping manufacturers achieve new levels of