Assembly and Inspection Automation

McIver Engineering & Controls provides automation systems that integrate robotics, vision inspection, and controls to streamline assembly, reduce errors, boost output, and ensure compliance across automotive, food and beverage, life sciences, and consumer goods industries.

Assembly and Inspection Automation

Industrial Automation Solutions for Assembly Efficiency

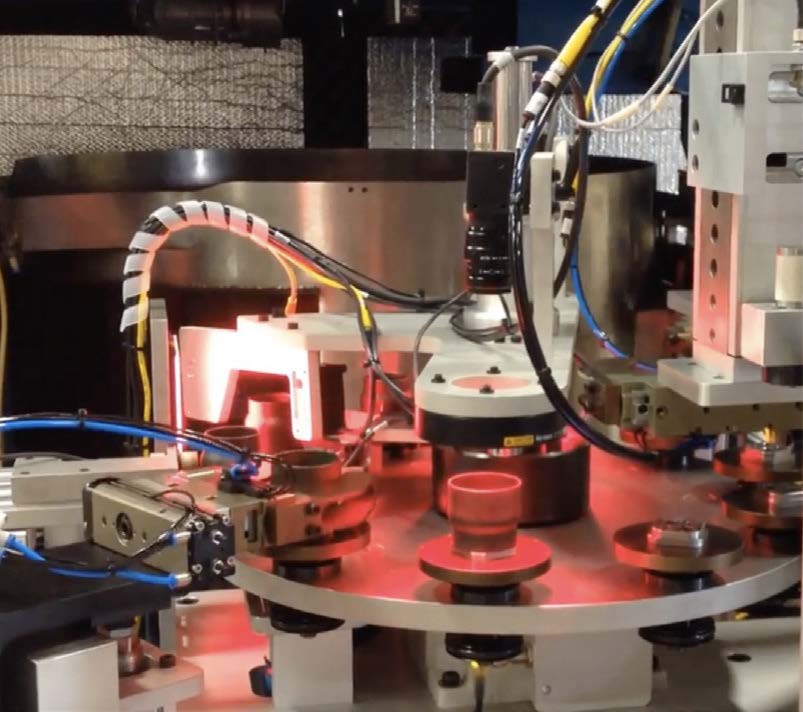

McIver Engineering & Controls delivers advanced assembly automation systems designed to improve precision, efficiency, and consistency. Our expertise includes robotic and servo-driven assembly, automated feeding and positioning, pressing and joining, part marking, and custom tooling. As a trusted automation engineering company, we provide scalable solutions tailored to your production needs across industries.

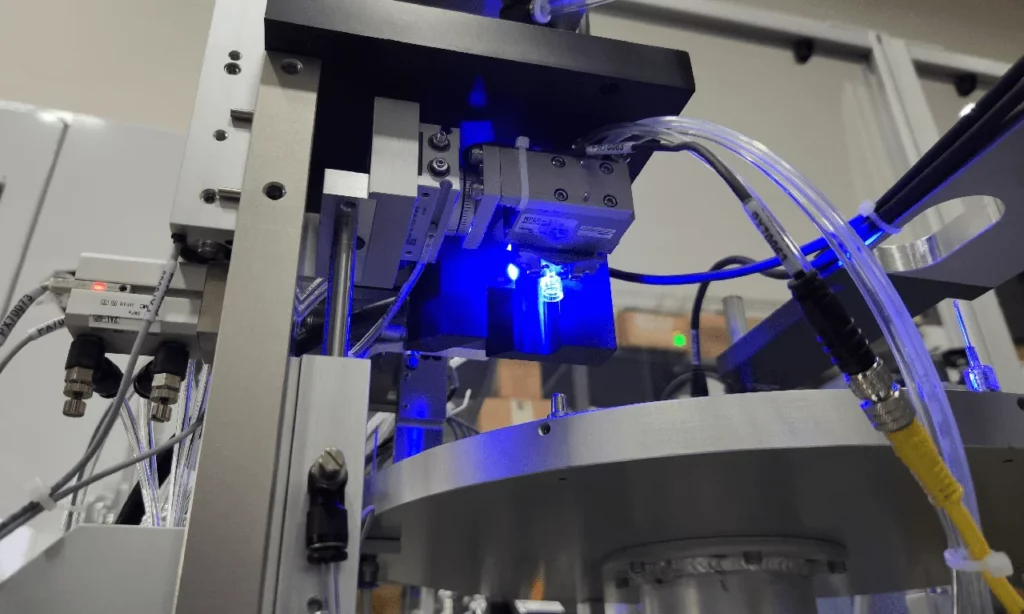

Industrial Automation Solutions for Reliable Inspection

McIver Engineering & Controls provides advanced inspection automation systems that improve quality, accuracy, and compliance. Our solutions include vision inspection with FANUC, Cognex, and Keyence, automated rejection handling, AI-powered defect detection, and integrated data collection for full traceability. Trusted across industries from consumer goods to medical device manufacturing, our robotic inspection systems ensure consistent results and reduced waste.

Assembly and Inspection Automation

At McIver Engineering & Controls, we design and build automation systems that integrate robotics, vision tools, and controls to elevate your assembly and inspection processes. Our user-friendly solutions are engineered to accelerate production, lower labor costs, and improve product quality while meeting the specific needs of your operation.

From mechanical design to robotics and vision inspection, our team delivers complete automation systems under one roof. We serve industries including automotive, food and beverage, life sciences, consumer goods, and heavy equipment, providing scalable solutions that enhance efficiency, accuracy, and safety.

Key Benefits of Assembly and Inspection Automation

- Increased output and reduced costs with improved cycle times

- Enhanced quality and compliance through automated vision checks

- Flexible systems that scale with your business and product needs

- Safer workplaces by automating repetitive or hazardous tasks

- Full traceability with logged part data and inspection results

- Code-compliant systems built to UL and NFPA standards

Your Trusted Automation Partner

McIver Engineering & Controls goes beyond equipment delivery. We provide intelligent, reliable automation solutions that improve efficiency, reduce errors, and support continuous improvement.

Contact McIver Engineering & Controls today to discuss your assembly and inspection automation project and discover how our solutions can transform your production.

Everything You Need to Know About Assembly and Inspection Automation

What is assembly and inspection automation?

How does a vision inspection system improve quality control?

Can assembly automation integrate with my existing equipment?

What industries benefit most from automated inspection systems?

How does assembly automation improve efficiency?

By automating repetitive tasks, aligning components with precision, and verifying quality instantly, assembly automation reduces cycle times and eliminates costly rework. Combined with automated inspection, manufacturers can achieve consistent quality output while maximizing productivity and return on investment.

Success Stories in Industrial Automation

Let’s Talk About Your Automation Project

Connect with

Our Team

Insights That Drive Innovation

Industrial Automation Resources

Explore expert perspectives from McIver Engineering & Controls on industrial automation. Our blogs and articles highlight trends, technologies, and real applications that improve efficiency, safety, and quality across industries.

In today’s competitive manufacturing environment, automating material handling has become essential for improving efficiency, reducing manual labor, and maintaining product consistency. Choosing the best palletizing and depalletizing system requires more

In today’s competitive manufacturing landscape, accuracy, consistency, and efficiency define success. As global markets demand higher output and uncompromising quality, manufacturers are increasingly turning to industrial automation to stay ahead.

In today’s manufacturing environment, efficiency and precision define success. Industrial automation has become the cornerstone of modern production, and leading robotic automation companies are helping manufacturers achieve new levels of