Semi-Automatic Systems

McIver Engineering & Controls delivers simple, single-purpose systems to complex, multi-variant/purpose semi-automatic automation systems, integrating your operators with precise, efficient, and injury-minimizing assembly or testing processes.

Single Purpose to Multi-Purpose Automation

Having issues with operator retention, injuries, or maintaining quality levels? McIver can help with our unique approach to understanding your current manual process to then guide you with smaller semi-automatic automation systems and grow with you as your automation maturity expands to fully automated “lights out” systems.

Explore Small Scale Automation Systems

Your First Step Toward Automation Starts Here

Semi-Automatic Systems for Multi-Variant Production

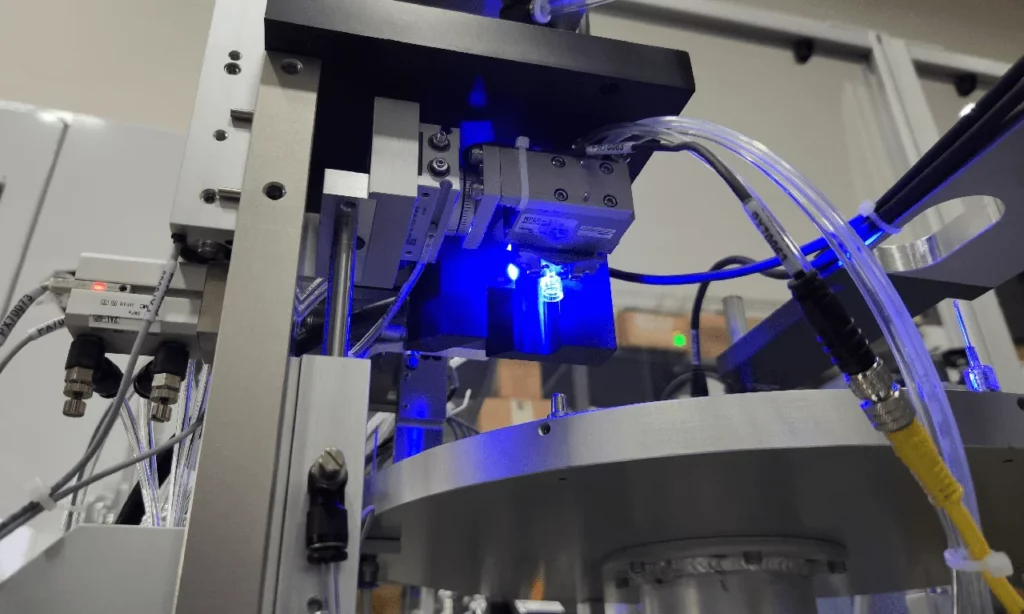

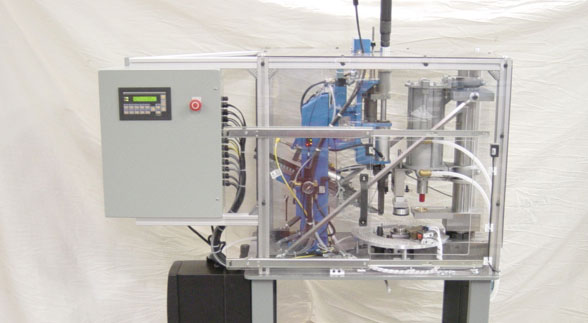

Semi-Automated Press & Inspect Solutions

Whether in automotive, food, pharma, or defense, press and inspect processes demand precision. McIver delivers semi-automatic systems that integrate human operators with automation for accuracy, efficiency, and reliability. With countless systems installed, we help manufacturers improve quality control while reducing operator strain and production errors.

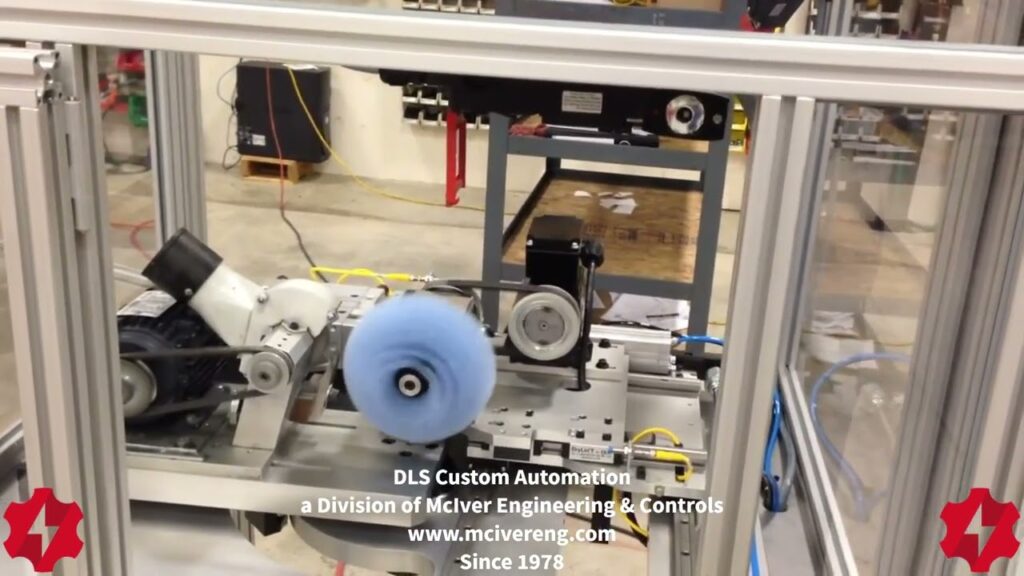

Semi-Automated Torque & Inspect Solutions

Semi-Automatic Brush Trimming & Inspection

Semi-automated torque and inspect systems are vital for quality production. Our brush trimmer example demonstrates how lean automation simplifies shaping unique brushes used in automotive and home applications. McIver Engineering & Controls develops semi-automatic solutions that reduce manual effort, improve consistency, and enhance product quality across industries.

Lean Semi-Automatic Success Stories

FAQ’s