Industrial Automation for Material Handling

Robotic and Lean Semi-Automatic

Material Handling Solutions

One line description McIver Engineering & Controls designs material handling systems that combine robotics and lean semi-automatic solutions to improve efficiency, accuracy, and safety across industries.

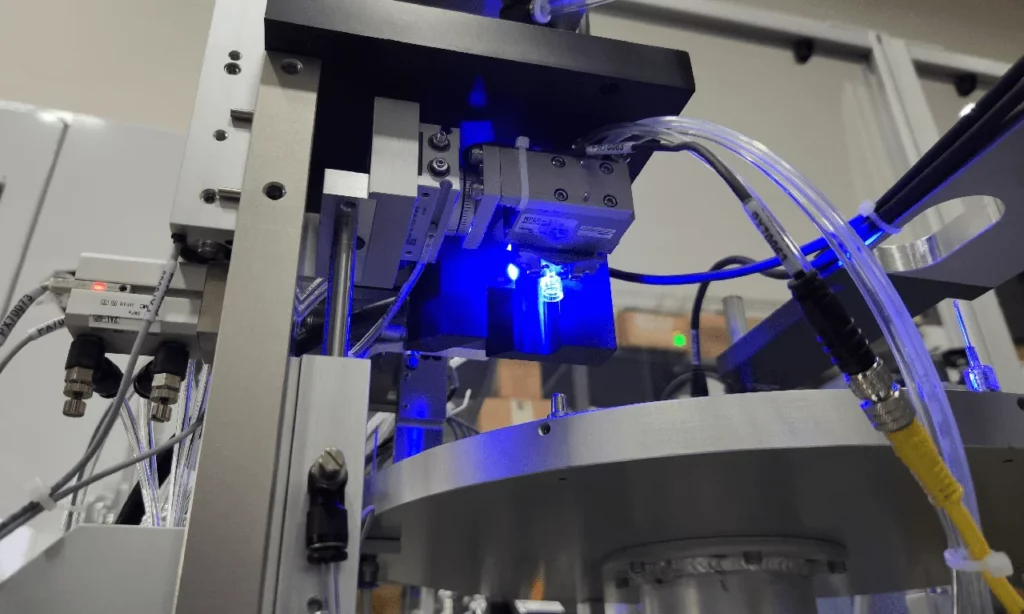

Lean Semi Automatic Material Handling Solutions

McIver Engineering & Controls designs lean semi-automatic material handling systems that improve efficiency, accuracy, and safety across production environments. By combining operator oversight with intelligent automation, our solutions reduce manual handling, boost throughput, and minimize errors. Trusted in industries from packaging to life sciences, we deliver scalable, reliable systems tailored to your facility.

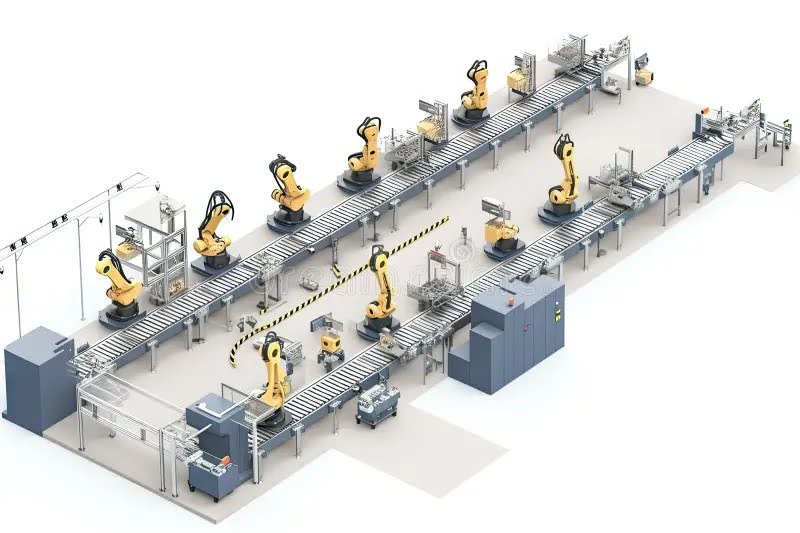

Smarter Material Flow with Robotic Automation

McIver Engineering & Controls delivers robotic material handling and traffic automation solutions that improve efficiency, accuracy, and safety across production environments. Our systems integrate FANUC robotics, conveyors, AGVs, and advanced controls to reduce manual handling, increase throughput, and ensure continuous, coordinated workflow. Trusted across industries from packaging to life sciences, we design scalable robotic solutions that meet the highest standards of quality and reliability.

Material Handling and Traffic Automation

At McIver Engineering & Controls, we design material handling and traffic automation systems that enhance efficiency, precision, and safety across your facility. Our solutions integrate robotics, conveyors, AGVs, and advanced controls to create seamless material flow from raw intake to finished goods dispatch.

By reducing manual handling, our systems increase throughput, minimize errors, and ensure smooth coordination between equipment, processes, and operators. Each solution is engineered for reliability, scalability, and 24/7 performance in demanding industrial environments.

What Our Systems Deliver

- Optimized flow of raw materials, WIP, and finished goods

- Faster cycle times with improved accuracy and consistency

- Intelligent traffic management with AGVs and AMRs

- Zone-based safety systems and real-time coordination

- Scalable solutions tailored to your facility and industry

Smarter Internal Logistics

McIver Engineering & Controls builds automation systems trusted in packaging, pulp and paper, life sciences, medical manufacturing, and other industrial sectors. As a FANUC Authorized System Integrator and UL-certified panel shop, we ensure every solution meets the highest standards of quality, compliance, and long-term reliability.

Ready to take the next step? Contact McIver Engineering & Controls today at (262) 783 9912 or request a quote to begin building a smarter, safer, and more connected operation.

Frequently Asked Questions

What is material handling and traffic automation?

Why is automation important in material handling?

How do industrial control panels fit into material handling systems?

What industries benefit from material handling automation?

Can McIver Engineering & Controls integrate new industrial automation with my existing systems?

Our engineering team specializes in integrating new material handling solutions with existing industrial automation equipment and infrastructure. Whether you need a retrofit or a complete system upgrade, we design solutions that fit your operation and budget.

How McIver Delivers Industrial Automation and Material Handling Results

Ready to Begin

Let’s Talk About Your Automation Project

Contact us

Fill the form to to get a free quote today

Industrial and Robotic Automation Blog

Read expert blogs from McIver Engineering & Controls covering industrial automation and robotic automation. Discover trends, solutions, and proven strategies that improve efficiency, quality, and safety in manufacturing.

In today’s competitive manufacturing environment, automating material handling has become essential for improving efficiency, reducing manual labor, and maintaining product consistency. Choosing the best palletizing and depalletizing system requires more

In today’s competitive manufacturing landscape, accuracy, consistency, and efficiency define success. As global markets demand higher output and uncompromising quality, manufacturers are increasingly turning to industrial automation to stay ahead.

In today’s manufacturing environment, efficiency and precision define success. Industrial automation has become the cornerstone of modern production, and leading robotic automation companies are helping manufacturers achieve new levels of