Machine Tending Automation

Lean Semi Automatic and

Robotic Automation Solutions

Lean Machine Tending Automation for Modern Manufacturing

McIver Engineering & Controls delivers lean semi-automatic machine tending automation solutions that combine operator expertise with advanced robotics for safer, faster, and more precise production. Designed to reduce downtime, improve part quality, and enhance efficiency, our solutions bring measurable results across industries. Partner with an automation engineering company trusted for innovation and reliability.

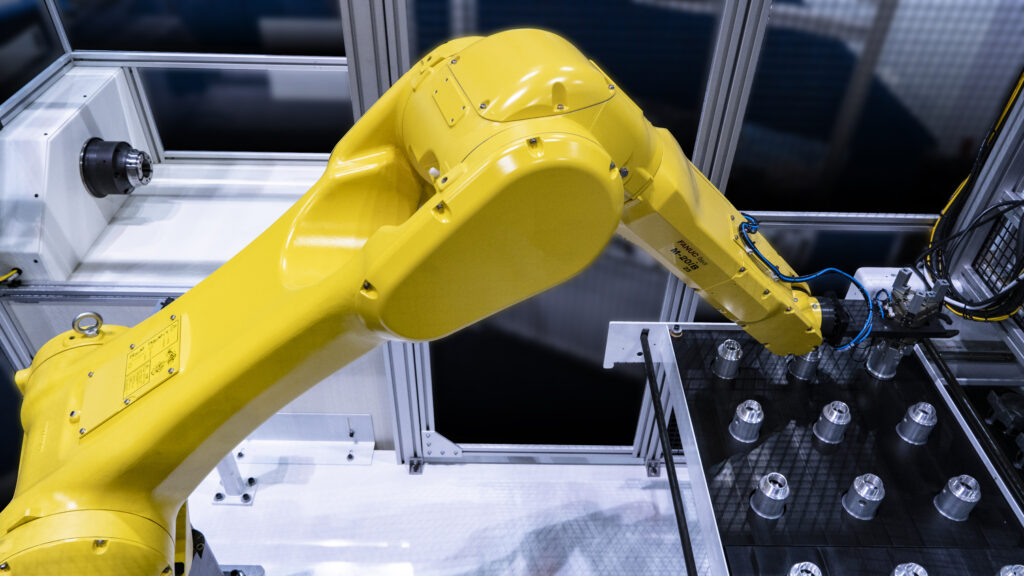

Industrial Automation with Robotic Machine Tending

Machine Tending Automation

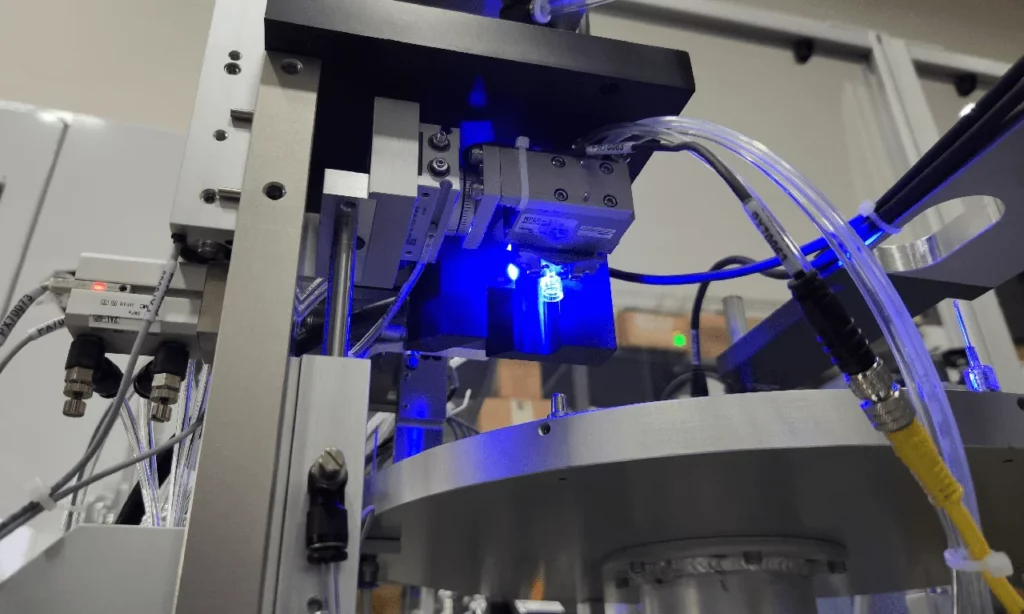

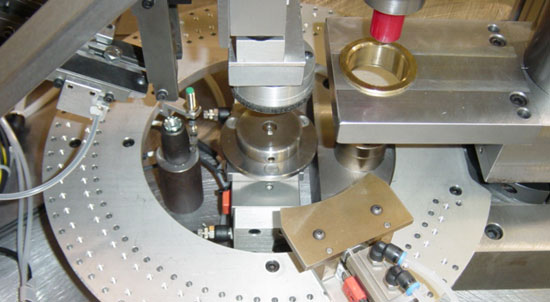

At McIver Engineering & Controls, our machine tending automation solutions bring measurable efficiency, repeatability, and safety to manufacturing operations. By replacing manual loading and unloading of CNC machines, injection molders, stamping presses, and other equipment, we deliver reliable robotic or lean semi-automatic systems that balance automation with human oversight.

Whether your focus is high-volume machining or low-mix custom fabrication, our solutions reduce downtime, improve quality, and minimize worker risk while supporting continuous improvement across your production floor.

The Benefits of Machine Tending Automation

- Improved worker safety by reducing exposure to repetitive or hazardous tasks

- Reduced labor costs and greater workforce efficiency

- Consistent part quality with precise and repeatable handling

- Lower machine idle time and higher utilization

- Scalable systems that adapt to changing production demands

Partner with McIver Engineering & Controls

From design and simulation to installation and long-term service, we provide complete support for your automation journey. All systems are engineered to meet stringent safety and quality standards, ensuring dependable performance for years to come.

Ready to take the next step? Contact McIver Engineering & Controls today to request a quote or call 262-783-9912 to speak with a machine tending specialist.

Frequently Asked Questions

What is machine tending automation?

What are the benefits of machine tending automation?

Can machine tending automation work with my existing equipment?

What role do industrial control panels play in machine tending automation?

Which industries benefit from machine tending automation?

How does McIver Engineering & Controls approach a machine-tending automation project?

Proven Machine Tending Automation in Action

Whether you need robotic palletizing, control panels, or full-scale automation, McIver Engineering & Controls provides turnkey systems that deliver measurable success.

Let’s Talk About Your Automation Project

Connect with

Our Team

Expert Perspectives

Industrial Automation Blogs by McIver Engineering & Controls

Gain insights from an experienced automation engineering company. Our blogs cover industrial automation strategies, robotic automation solutions, and innovations driving efficiency and reliability in modern manufacturing.

In today’s competitive manufacturing environment, automating material handling has become essential for improving efficiency, reducing manual labor, and maintaining product consistency. Choosing the best palletizing and depalletizing system requires more

In today’s competitive manufacturing landscape, accuracy, consistency, and efficiency define success. As global markets demand higher output and uncompromising quality, manufacturers are increasingly turning to industrial automation to stay ahead.

In today’s manufacturing environment, efficiency and precision define success. Industrial automation has become the cornerstone of modern production, and leading robotic automation companies are helping manufacturers achieve new levels of