Industry Leading Quality Standards

Whether we are producing a custom one-off design or high-volume production runs, we are the right team for the job.

Everything starts with a design review and project kick-off meeting. This allows our Team to review all the project-specific details to ensure things run smoothly. During the design review process, we will carefully examine the design to identify any safety, certification, or functionality issues that might arise. We will inform you if any problems are discovered and provide a solution. Furthermore, if we believe there are ways to simplify or improve your design, we will offer suggestions to help you achieve your goals.

Next, the Project Management Team will order the necessary components and add the build to the production schedule. Our Team of professionals will purchase the highest quality components from the most reputable sources. All components supplied by McIver Engineering & Controls are guaranteed following the manufacturer’s warranty policies, and only new, certified components will be purchased and used in the manufacturing process unless otherwise requested by the customer. Adhering to these sourcing standards is one of the many ways we consistently deliver the best quality products to our customers.

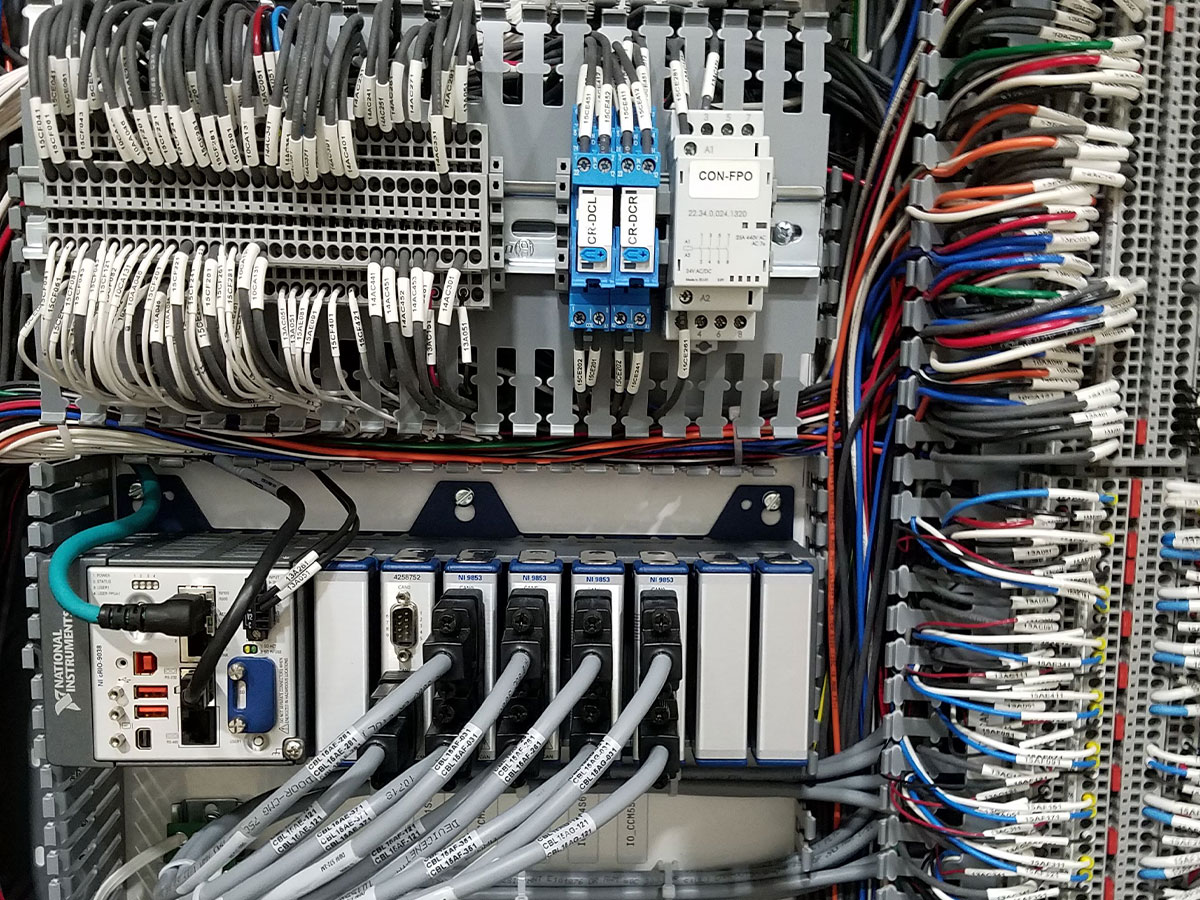

- Computer-generated wire labels guarantee legibility and durability.

- All wiring harnesses are neatly combed and include 20% spare conductors for future expansion.

- All PLC/IO points, including spares and door-mounted devices, are run to terminal strips.

- All large and heavy components are mounted on studs.

At McIver Engineering & Controls, everything we do is centered around providing the highest quality and safest solutions possible.

For your next custom industrial control panel requirement, trust the expert team at McIver Engineering & Controls Solutions.