Industrial electrical control panels are the nerve centers of modern operations — they direct the seamless interactions between machinery, processes, and systems, housing and organizing components that manage everything from power distribution to automated control. Ultimately, their purpose is to ensure efficiency, safety, and reliability in even the most demanding environments.

The choice of components — from circuit breakers and relays to programmable logic controllers (PLCs) and sensors — can make or break your system’s performance. Whether you need a new industrial control panel design or are upgrading an existing one, the right components are key to achieving maximum functionality.

The Core Components of Industrial Electrical Control Panels

Industrial electrical control panels work by receiving inputs, processing them according to programmed logic, and generating outputs to regulate equipment. To achieve this, they rely on a combination of components.

Hardware Components

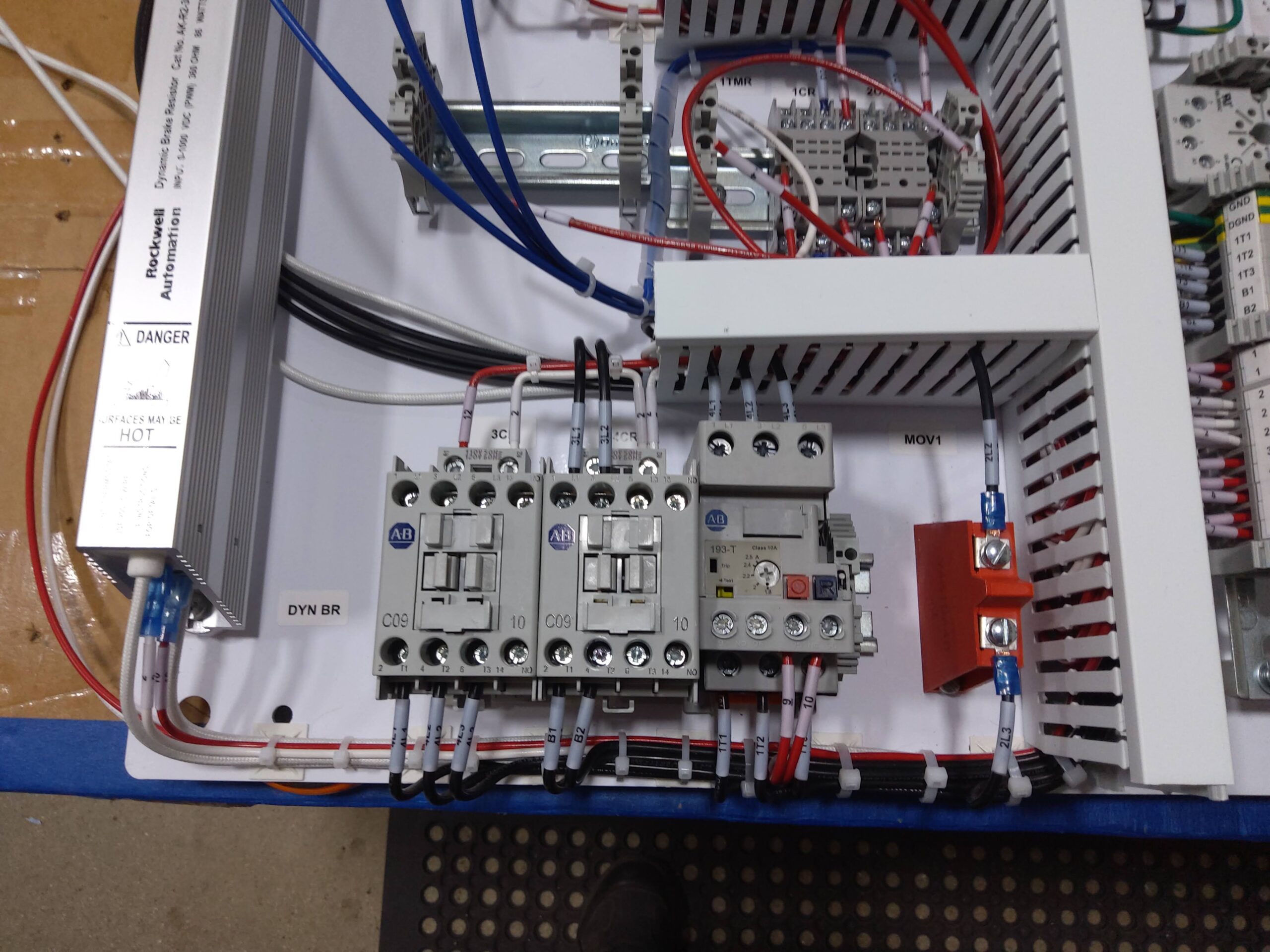

The hardware forms the physical backbone. These components include power supply units, which convert incoming electrical power into usable voltages for the panel’s devices. Circuit breakers and fuses, which relays and contactors enable or disable, protect the system by interrupting the electrical flow in case of overloads or short circuits.

PLCs are the brains that execute programmed logic. At the same time, sensors and input devices detect conditions such as temperature, pressure, or motion and send signals to the PLC for processing. Human-machine interfaces (HMIs) provide a user-friendly interface for operators to monitor and control the system. Lastly, wiring and terminal blocks facilitate connections between all components.

Software Components

If hardware executes the operations, software defines how those operations unfold. Software components bring intelligence and flexibility to the control panel; without them, the hardware cannot function cohesively. They also offer adaptability to changing requirements and enable precise control over processes.

Examples include programming software for PLCs that creates custom logic for tasks like timing, sequencing, and decision-making. SCADA (Supervisory Control and Data Acquisition) systems give real-time data visualization, remote monitoring, and control, while diagnostic and maintenance tools help identify issues and run diagnostics.

What Makes an Industrial Electrical Control Panel Component “Right”?

Every industrial control panel is unique. As such, one company’s “right” component may not necessarily be the “right” component for another. For instance, a control panel designed for a high-temperature, heavy-duty manufacturing facility may require components rated for extreme conditions, such as heat-resistant relays and heavy-duty fuses. On the other hand, a control panel for a more sensitive, automated laboratory environment might prioritize precision and smaller, more compact components.

The right components cater to your company’s long-term goals and distinct demands. They tick all the boxes for compatibility, scalability, and ease of maintenance, guaranteeing smooth operation and longevity. Moreover, they must align with the regulatory standards and industry-specific certifications.

How To Choose the Right Components

The sheer number of factors to consider regarding industrial control panel design makes it easy to feel perplexed. Every decision has significant consequences. Here are three tips to guide your selection of the right components.

Identify Your Industry-Specific Needs

Different industries have different requirements. If you work in the food processing industry, you may benefit from components that are rated for wash-down environments or are resistant to corrosion. If you are in the high-speed automotive production sector, components that can handle heavy loads and provide rapid response times are more suitable. Take into account the following:

- Environmental Conditions: Temperature extremes, humidity, chemical exposure, or the potential for dust or moisture.

- Power Needs: The size and capacity of power supplies, circuit breakers, and relays.

- Automation Level: Basic on/off control or complex, multi-stage automation.

Consider Usage

Think about how the system will be used on a day-to-day basis. User-friendliness and ease of maintenance directly affect the overall efficiency, uptime, and long-term performance. Generally, the simpler and more intuitive your system is, the less likely you are to go through errors, delays, or accidents. Go for components with easy-to-understand navigation; consider how possible it will be for operators to learn and master them for straightforward upkeep, troubleshooting, and upgrades.

Prioritize Regulatory Compliance

Control panels must always adhere to strict industry codes and standards. Every component you choose must point toward the end goal of complying with the following and more regulations and certifications:

- UL 508A (Industrial Control Panels Intended for General Use)

- UL 698A (Industrial Control Panels Relating to Hazardous (Classified) Locations)

- NFPA 70 (Safe Installation of Electrical Wiring and Equipment)

Working With a Control Panel Builder

A control panel builder brings expertise in assembling various components into a cohesive system. They are knowledgeable about industry standards, regulatory requirements, and best practices, properly selecting and integrating components. They can also offer guidance on component optimization.

Partnering with a control panel builder saves time and reduces risks, making it an investment in your success. How do you know you are working with a qualified builder?

Trust the team with extensive experience and a track record of successful projects. They should be able to communicate with you regularly, maintaining transparency throughout the entire process. Look for the ability to customize solutions and source high-quality components from trusted suppliers. Most importantly, the builder should deliver strong customer service and support.

McIver Engineering & Controls: Your Control Panel Builder

Choosing the right components for your industrial control panel design is pivotal. Fortunately, McIver Engineering & Controls, the leading UL 508A-certified control panel manufacturer, is ready to take over the task for you. With our commitment to quality and dedication to safety, you can expect top-tier solutions and unmatched value.

Request a quote to jumpstart your project with McIver Engineering & Controls today. To learn more about our services, call (262) 783-9912 or contact us online.